running compression test before breaking in an engine|good compression test numbers : bulk This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp. Free Classic Mahjong Solitaire. Rejoice, lovers of playing Fre.

{plog:ftitle_list}

WEBPeso limite: 100 kg Unidade Penha, 160kg nas unidades Jabaquara e Santana. Paciente maior de 18 anos é desobrigado a presença do responsável legal para a realização de .

how to fix primary hard disk self test

The ideal method of breaking in a top end is “dead running” the engine for a short time. The rotating assemblies should be lubed with an . This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp.

Before you can perform a compression test on your car’s engine, you’ll need to run it for 5 to 10 minutes to bring it up to its normal running . When Should You Perform an Engine Compression Test? You should run compression tests on each of your engine’s cylinders as early as possible if your vehicle shows any of the symptoms listed below: Regular (not .A vacuum test is a great way to determine an engine’s overall breathing capabilities but does not provide results for individual cylinders. The advantage of a running compression test is that it . If your engine is running rough or misfiring and you have ruled out your ignition and fuel system as the cause, it may be time for a compression test. Low compression will cause an incomplete burn of the air-fuel mixture .

how to format and test a hard drive windows 10

Proper engine break-in procedure is critical. . on a Wednesday night test & tune, back home at the Garage check everything over change the oil and back to full throttle. . in an effort to reduce warranty costs I assume they . Once that contact occurs, no amount of gentile running is going to fix that.” What is actually being done during engine break-in is fairly simple – it’s the controlled bedding, or wearing-in, of the new piston rings on the hone of . Familiarize Yourself with the Engine: Before starting the compression test, it is essential to have a good understanding of the engine’s layout and components.This knowledge will help you locate the necessary and access points for the test. Ensure Proper Ventilation: Compression testing involves running the engine, which produces exhaust gases.To . Running the Test. Before we get started, let’s talk about equipment. As we said, a compression test is fairly straightforward, requiring only one specialized item that you might not already have in your D.I.Y. toolbox: the compression tester itself. These usually cost between and , making them a valuable addition to any home garage.

Comparing measurements between cylinders is important. Running compression at idle should be 50-75 PSI (about half cranking compression). Snap throttle compression should be about 80% of cranking compression. Let’s analyze the results from the following sample test readings. In Example 1, cylinder #1 has a snap test reading that is Doing a compression test, is a good way to measure the condition of, the rings, cylinders, and valves. So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance.

A compression test diagnoses many engine problems. If a compression test is below the manufacturer's specifications, there's an internal engine issue. . This will indicate that the engine has run out of fuel. Warning: If you do not disable the fuel system then fuel will continue to be sprayed into the cylinder during the compression test . H igh oil consumption, excessive smoke through the exhaust, high blow-by, lower than expected power output and increased oil contamination are just some of the possible results of an improper engine break-in or run-in. While production engines in new vehicles are already “broken-in” at the factory, any high-performance “built” engine requires a proper break-in .Once all timing, fueling and other parameters are verified correct, run the engine for approximately 15-30 minutes. o Vary the RPM between 25-35% of the maximum engine rpm for the duration of the break-in. Allowing the engine to idle should be avoided if at all possible. o Listen for any unusual noises, shut down if necessary. In the last two issues of GEARS Magazine, we covered engine mechanical testing using high current probes for relative compression testing in conjunction with transducers for cranking vacuum testing.We also touched on in-cylinder cranking compression testing using a pressure transducer. This month we’ll expand our in-cylinder testing by using a pressure .

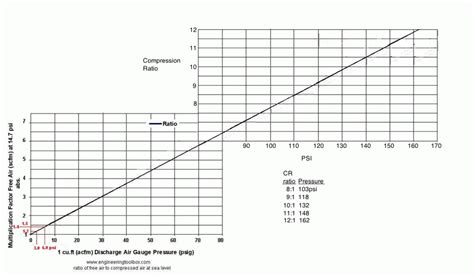

Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 . The main purposeof break-in is to seat the compression rings to the cylinder walls.Let me explain what ring seating is all about. . Some large overhaul shops alsogive their newly overhauled engines a test-cell run before shipment,but most shops don't. So be sure to ask if your engine was runand for how long. . Start the engine and run at .

From a functional standpoint, good engine compression is integral for proper engine operation. Thus, a compression test is an indispensable part of engine maintenance and troubleshooting. Understanding the Mechanics of Compression Testing. To conduct a compression test, a pressure gauge is attached to the place of the spark plug in the cylinder.

Each new or rebuilt engine is given a production test run at the factory before the engine is delivered to an aircraft manufacturer or customer. After installation in the aircraft, the engine is run again during the test flights. . For those who still think that running the engine hard during break-in falls into the category of cruel and . Reasons to perform a compression test. Before we get into how a compression test is performed, let’s take a look at why you might need one. Your engine is misfiring. If your engine is running rough or misfiring and you . A compression test is a simple and effective way to determine if your engine has low compression. Here’s how to perform a compression test: Start by warming up your engine to operating temperature. Remove the spark . Testing the engine compression on your Chevrolet or GMC 4.8L, 5.0L, or 6.0L engine is not hard to do. A compression test will help you to determine the health of your engine by measuring the pressure of the air that .

One standard practice is to run a compression test before buying a used boat. This pre-purchase assessment prevents you from unknowingly buying a boat with engine problems. . After a compression test or any type of repair, make sure to break in your boat engine properly. This will ensure the longevity of any replaced components and help . What to Consider Before Breaking In New Running Shoes. Now that we’ve covered how long running shoes last, it’s important to note a few important factors you’ll want to consider before breaking in your new running shoes. Firstly, you’ll want to consider the brand and make of your new running shoes. Compression Test. A compression test is a useful first step in diagnosing a bent connecting rod. This test measures the pressure built up in each cylinder of your engine while it’s cranking. To perform a compression test, you’ll need a compression tester. Here’s what to do: Warm up your engine. Turn off your engine, and remove all spark .

Study with Quizlet and memorize flashcards containing terms like A compression test shows that one cylinder is too low. A leakage test on that cylinder shows that there is excessive leakage. During the test, air could be heard coming from the tailpipe. Which of the following could be the cause? A. Broken piston rings B. Bad head gasket C. Bad exhaust gasket D. An exhaust valve .Understanding the Remanufactured Engine: Before diving into the break-in process, it’s essential to understand what a remanufactured engine is. Fraser Engines specializes in remanufacturing engines, a process that involves disassembling, cleaning, inspecting, and replacing or repairing worn-out parts to meet or exceed original specifications. .

A compression test is an excellent way to determine the condition of your engine. Among many other things, it will reveal the state of the valves, cylinders, rings, valve seats, and how these parts are wearing out. If you notice your engine generating low power than usual or running rough, consider carrying out a compression test to find out the problem. For the test, you’ll need to: * Raise the outboard motor to a level surface, such as a hoist or jack * Make sure the engine is secure and won’t move during the test * Ensure the spark plug wires are properly connected By positioning the engine correctly, you’ll be able to get a accurate reading and avoid any potential damage to the engine. I was breaking in my engine keeping a close eye on the temp and oil pressure. Oil was around 60. My engine seemed to be running hot, but I was trusting the manual temp gauge. Some smoke was coming of the breather, I looked at the gauge and it was 180. When it got to 190 and showed no signs of slowing down I attempted to turn engine off.

Piston rings, valve seats, and other critical components are designed to expand as they heat, which creates the desired compression ratio inside the engine. If you complete a compression test on a cold engine, the reading will be inaccurate. Completely shut off the engine. To complete a compression test, the engine needs to be shut off. Step 5: Perform the test. Attach the engine cylinder leak-down tester and air source. Don’t forget that the engine WILL most likely rotate back if you are on the compression stroke unless there is a huge leak. I usually add air and watch the crankshaft pulley for the first run. If I am on the compression stroke the engine should spin, or at .

running compression vs cranking

running compression test procedure

perform engine compression test

We would like to show you a description here but the site won’t allow us.

running compression test before breaking in an engine|good compression test numbers